In the rapidly evolving electronics sector, the integration of technology and innovation has led to remarkable advancements in printed circuit board (PCB) design. One such advancement is the rise of rigid flex PCBs, which combine the best of both rigid and flexible PCB technologies. These versatile components are increasingly recognized for their ability to meet the complex demands of modern devices, particularly in sectors like consumer electronics, medical devices, and aerospace. John Smith, a leading expert in PCB technology, emphasizes this trend by stating, “Rigid flex designs are not just a choice; they are becoming a necessity for manufacturers seeking to create compact and durable electronic solutions.”

As industries embrace miniaturization and enhanced functionality, rigid flex PCBs offer unparalleled benefits such as reduced weight, increased reliability, and improved assembly efficiency. The unique design capabilities of rigid flex allow for intricate layouts that facilitate innovative product designs, leading to more efficient and streamlined devices. Furthermore, with the continuous advancements in materials and manufacturing processes, rigid flex PCBs are poised to become a cornerstone in the future of electronic applications, opening up new avenues for creativity and engineering excellence.

Understanding the benefits, applications, and emerging trends in the rigid flex PCB industry is crucial for manufacturers and designers aiming to keep pace with the ever-changing technology landscape. As the demand for high-performance electronics grows, rigid flex technology stands as a pivotal solution that caters to both consumer expectations and industry requirements.

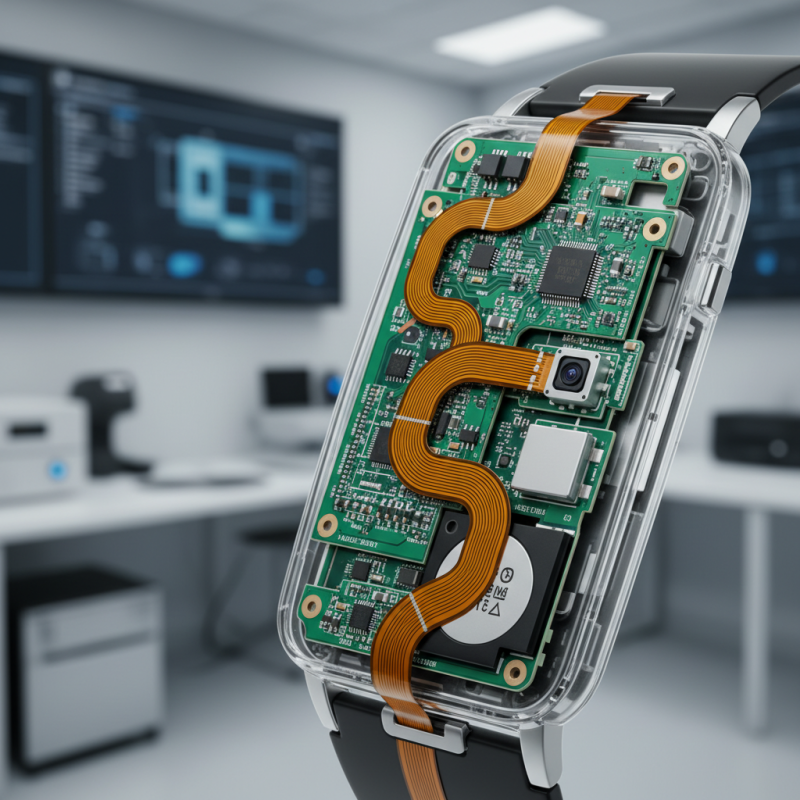

Rigid flex PCBs, which combine the best features of rigid and flexible circuit boards, are becoming increasingly popular in various industries. The core of this technology is the integration of rigid regions that provide structural support with flexible areas that enable complex geometries and space-efficient designs. This versatility allows for more compact designs compared to traditional rigid PCBs, which is essential in applications where space and weight are critical, such as in aerospace and medical devices.

The design of rigid flex PCBs involves meticulous planning and innovative engineering to ensure that electrical performance and mechanical reliability are maintained. Key factors in the design process include layer stacking, material selection, and the establishment of appropriate bend radii. Designers often utilize advanced CAD tools to simulate the board’s performance under various conditions, ensuring that both electrical and physical demands are met. As the industry trends towards miniaturization and increased functionality, rigid flex PCBs present an effective solution, facilitating advancements in technology while optimizing design efficiency.

Rigid flex PCBs have emerged as a pivotal technology in modern electronics, offering a multitude of advantages that cater to the needs of complex devices. One of the key benefits of rigid flex PCBs is their ability to optimize space and reduce weight. By integrating rigid and flexible circuitry, these boards allow for more compact designs, which is essential in the development of portable and lightweight electronic devices. This space-saving capability is particularly beneficial in industries such as consumer electronics and medical devices, where miniaturization is critical.

Another significant advantage of rigid flex PCBs is their enhanced reliability. The combination of rigid and flexible sections minimizes the stress and strain on the components during assembly and operation, leading to lower failure rates. This durability makes them suitable for demanding applications, including aerospace and automotive industries, where performance and safety are paramount. Moreover, their capability to withstand harsh environments adds another layer of attractiveness for manufacturers looking for long-lasting solutions.

**Tips:** When considering rigid flex PCBs for your design, evaluate the specific requirements of your application, such as environmental factors and space constraints. Additionally, collaborating closely with your PCB manufacturer can yield insights into optimizing the design for performance and cost-effectiveness, ensuring you leverage the full benefits of this innovative technology.

This chart illustrates the key benefits of rigid flex printed circuit boards (PCBs) in modern electronics, highlighting their significant advantages such as cost efficiency, space savings, improved reliability, design flexibility, and weight reduction, all crucial for enhancing electronic device performance.

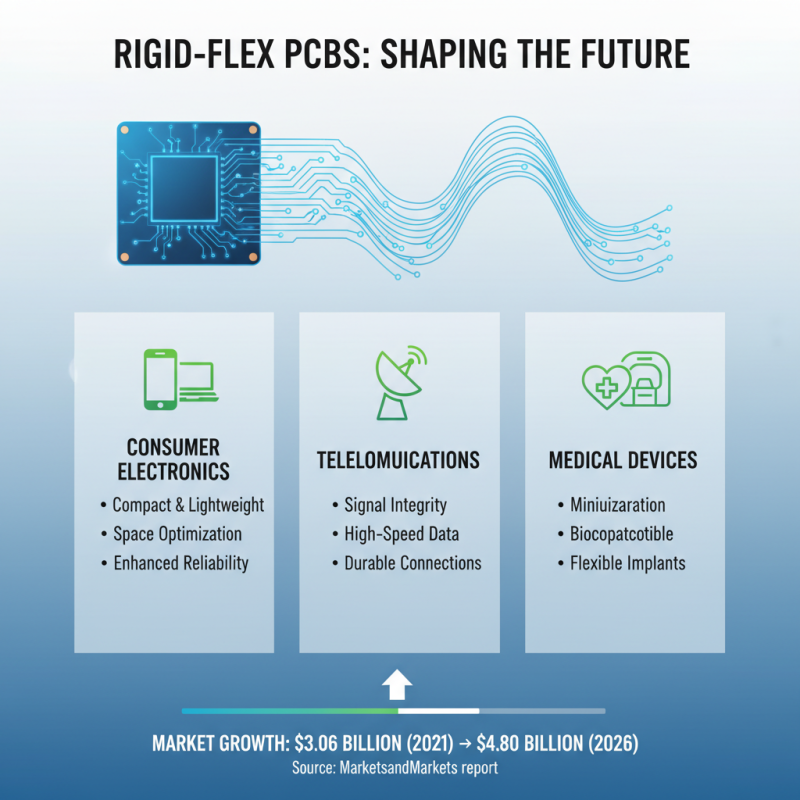

Rigid flex PCBs, which integrate both rigid and flexible circuit technologies, have become increasingly vital across various industries due to their unique advantages. In the consumer electronics sector, for example, these PCBs facilitate the development of compact and lightweight devices, optimizing space while enhancing reliability. According to a report by MarketsandMarkets, the rigid flex PCB market is projected to grow from USD 3.06 billion in 2021 to USD 4.80 billion by 2026, underscoring their rising importance in consumer electronics, telecommunications, and medical devices.

In the automotive industry, rigid flex PCBs play a critical role in the advancement of smart vehicle technologies. They are integral in various applications, including infotainment systems, advanced driver-assistance systems (ADAS), and improved connectivity features. A study by ResearchAndMarkets highlights that the automotive PCB market, which includes rigid flex solutions, is expected to reach USD 15.79 billion by 2025, driven by the increasing demand for high-performance and miniaturized electronic components. This alignment with industry trends illustrates how rigid flex PCBs are becoming essential for enabling innovation in modern automotive design.

The rigid flex PCB market is experiencing significant transformations driven by advancements in technology and shifting consumer demands. According to a report by MarketsandMarkets, the rigid flex PCB market is projected to reach USD 22.3 billion by 2025, growing at a CAGR of approximately 10.3% from 2020. This growth is primarily fueled by the increasing miniaturization of electronic devices and the rising demand in sectors such as consumer electronics, automotive, and medical devices. Manufacturers are investing in innovative materials and processes to enhance performance and reliability while also addressing the complexity of multi-layer circuit designs.

Current trends in rigid flex PCB manufacturing reflect a broader industry movement towards sustainability and efficiency. The integration of automation and advanced manufacturing technologies is optimizing production processes, reducing waste, and improving yield rates. Additionally, there is a growing emphasis on developing eco-friendly materials to meet environmental regulations and enhance product lifecycle management. A study by Research and Markets highlights that the adoption of green technologies in PCB manufacturing not only supports compliance with global standards but also attracts environmentally conscious consumers, positioning companies favorably in the evolving market landscape. These trends indicate a robust commitment to adapting practices that sustain both industry growth and ecological responsibility.

The rapidly evolving landscape of rigid flex PCB production is marked by several challenges, particularly in the areas of material selection, manufacturing consistency, and integration with other electronic components. According to a recent industry report, over 60% of manufacturers cite material reliability as a significant obstacle, particularly when balancing flexibility and durability. As devices become smaller and more complex, the demand for rigid flex PCBs continues to rise, necessitating advanced solutions to these challenges.

One effective solution is the adoption of advanced manufacturing techniques, such as additive manufacturing and automated visual inspection technologies. These techniques not only enhance production efficiency but also improve the overall quality of the PCBs. Furthermore, employing advanced simulation tools during the design phase helps predict potential integration issues, allowing engineers to address them proactively. Studies indicate that companies implementing these technologies report a reduction in production defects by up to 45%.

**Tip:** When selecting materials for rigid flex PCBs, consider factors like thermal stability and dimensional reliability to ensure optimal performance under varying conditions.

As integration demands increase with the rise of IoT devices, developing robust testing protocols becomes paramount. The complexity of these assemblies requires comprehensive testing at multiple stages, from production to deployment. Integrating real-time monitoring systems can help identify issues early, safeguarding against costly failures. Research indicates that organizations prioritizing rigorous testing protocols see a dramatic decrease in failure rates, highlighting the importance of quality assurance in today’s competitive market.

**Tip:** Incorporate rigorous testing strategies into your production workflow to enhance reliability and reduce long-term costs associated with product recalls or failures.

| Aspect | Details |

|---|---|

| Material Types | Polyimide, FR-4, Copper |

| Thickness Range | 0.2 mm to 2.0 mm |

| Common Applications | Consumer Electronics, Medical Devices, Aerospace |

| Key Benefits | Space-saving, Weight reduction, Increased Flexibility |

| Challenges in Production | Cost, Complexity, Reliability |

| Integration Solutions | Advanced Design Software, Custom Manufacturing Processes |

| Trends in Industry | Miniaturization, Automation, Sustainable Materials |

| Future Outlook | Increased adoption in IoT Devices, Continued Innovations |