In the rapidly evolving landscape of technology, the demand for efficient and cost-effective production methods in circuit board manufacturing has never been greater. As companies strive to improve their bottom line while maintaining high-quality standards, optimizing manufacturing processes becomes imperative. According to Dr. Emily Tran, a renowned expert in electronic manufacturing processes, “To remain competitive in circuit board manufacturing, businesses must embrace innovation and seek continuous improvement in their operations.” This perspective highlights the critical need for manufacturers to rethink traditional approaches and adopt strategies that not only enhance efficiency but also reduce costs.

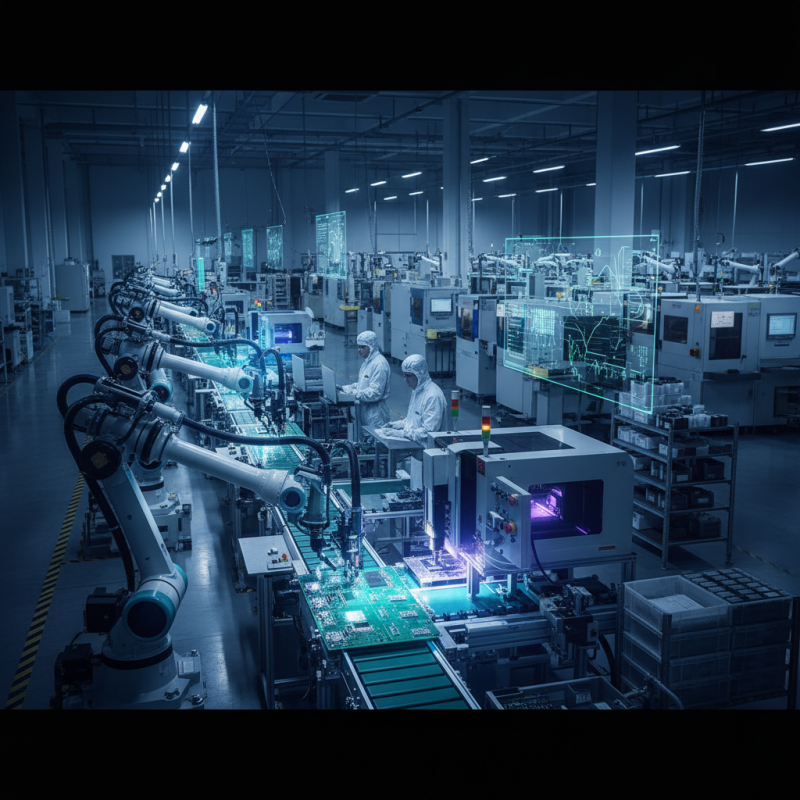

Efficiency in circuit board manufacturing can be achieved through a combination of modern technology, streamlined processes, and effective resource management. Companies are increasingly turning to automation and advanced manufacturing techniques to minimize waste and maximize output. By implementing lean manufacturing principles and leveraging data analytics, organizations can identify bottlenecks and optimize workflows, ensuring a smoother production cycle that meets the demands of the market.

Ultimately, the quest for cost savings in circuit board manufacturing is not solely about reducing expenses but also about investing in smarter production methodologies. As the industry continues to face challenges such as supply chain disruptions and fluctuating material costs, the importance of an agile and responsive manufacturing system becomes evident. In this article, we will explore key strategies that can be employed to optimize circuit board manufacturing processes for better efficiency and cost savings.

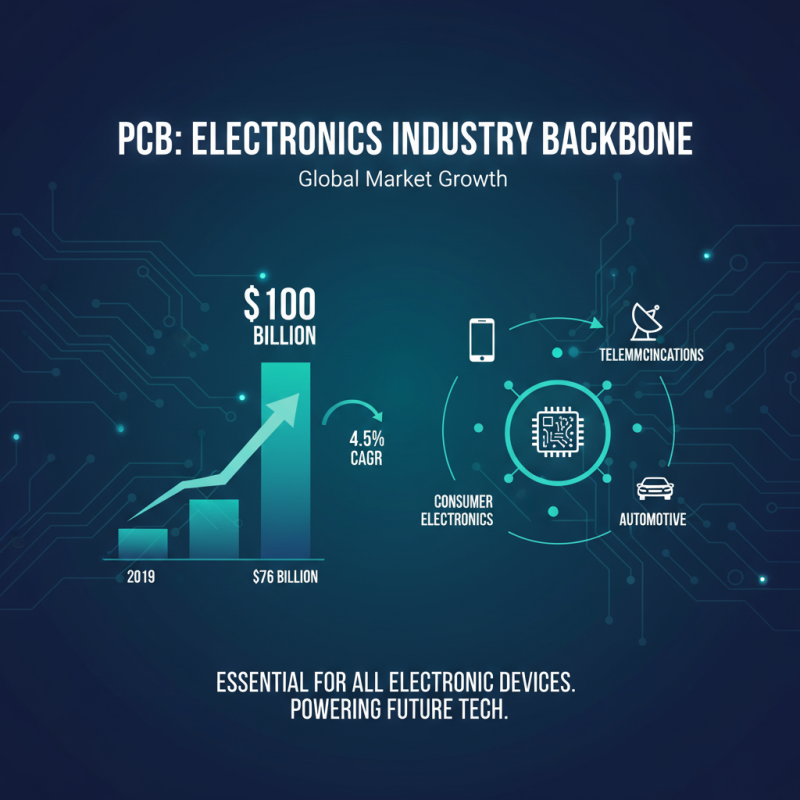

The importance of circuit board manufacturing in the electronics industry cannot be overstated, as it serves as the backbone for virtually every electronic device. According to a report by Market Research Future, the global printed circuit board (PCB) market is expected to reach approximately $100 billion by 2025, growing at a compound annual growth rate (CAGR) of around 4.5% from 2019. This growth underscores the critical role that PCBs play in enabling technological advancements across various sectors, including consumer electronics, telecommunications, and automotive industries.

In addition to their foundational role, circuit boards are pivotal in driving innovation and efficiency within the electronics sector. Electronic devices now require more complex and finely detailed designs that necessitate advanced manufacturing techniques. A study by IPC (Institute for Printed Circuits) highlights that approximately 30% of a PCB’s cost can be attributed to materials. Thus, optimizing the manufacturing process not only affects production efficiency but also has significant implications for cost savings. By investing in techniques such as automated manufacturing and lean production methods, companies can reduce waste and streamline their operations, ultimately enhancing their competitive edge in a rapidly evolving market.

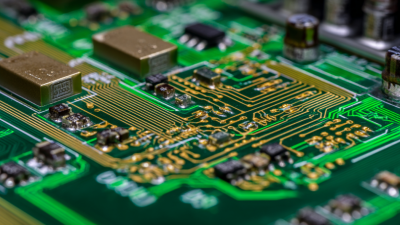

In the realm of PCB manufacturing, optimizing efficiency and cost savings is essential for maintaining competitiveness. A pivotal factor influencing production efficiency is the adoption of advanced manufacturing technologies. Recent studies show that implementing techniques such as automated pick-and-place machines and laser direct imaging can reduce production time by up to 30%. Automation not only streamlines processes but also minimizes human error, which can lead to costly reworks and delays.

Additionally, material selection plays a crucial role in enhancing productivity. High-quality materials that offer better thermal and electrical properties can lead to fewer failures and longer product lifespans. According to a report by IPC, leveraging superior materials can result in up to a 20% increase in yield rates, ultimately driving down costs associated with defective products and warranty claims. Furthermore, optimizing the supply chain for these materials can mitigate lead times, enabling manufacturers to respond more swiftly to market demands.

Lastly, a well-trained workforce is essential for maximizing operational efficiency. Training programs focused on the latest manufacturing processes can empower employees to utilize new technologies effectively, contributing to a significant increase in productivity. Research indicates that companies investing in employee development see a return on investment in productivity gains of upwards of 50%. By focusing on these key factors—technology adoption, material selection, and workforce training—PCB manufacturers can significantly enhance their efficiency and achieve substantial cost savings.

Cost analysis plays a crucial role in optimizing circuit board manufacturing, particularly in understanding material and labor expenses associated with Printed Circuit Board (PCB) production. Material costs are often the most significant expense in the manufacturing process. By selecting high-quality yet cost-effective materials, manufacturers can strike a balance between performance and affordability. Factors such as the type of substrate, copper weight, and solder mask can significantly influence overall material expenses. Engaging with multiple suppliers and negotiating bulk purchase agreements may also yield substantial savings and reduce production costs.

Labor expenses comprise another critical component of PCB production costs. Efficient workforce management can lead to reduced labor costs without sacrificing quality. Implementing automation in assembly processes can further streamline operations, minimize human error, and enhance production speed. Additionally, investing in employee training ensures that workers are skilled in using advanced machinery and best practices, which can lead to increased productivity. By analyzing both material and labor costs, manufacturers can identify areas for improvement, leading to enhanced efficiency and more substantial cost savings in the overall PCB production process.

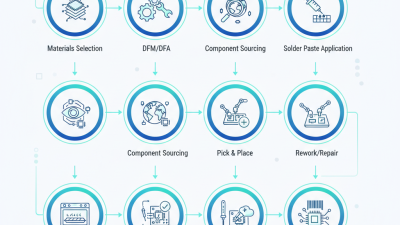

Implementing lean manufacturing techniques in circuit board fabrication is essential for enhancing overall efficiency and achieving substantial cost savings. The core principle of lean manufacturing is to eliminate waste while maximizing productivity. In the context of circuit board manufacturing, this can be achieved by streamlining processes, reducing cycle times, and optimizing resource allocation. By focusing on the value stream, manufacturers can identify non-value-adding activities that can be minimized or eliminated, thereby improving flow and reducing lead times.

One effective lean technique is the application of just-in-time (JIT) manufacturing, which ensures that materials and components are available only when needed in the production process. This reduces excess inventory, cutting down on storage costs and decreasing waste from obsolete components. Additionally, implementing standardized work procedures can lead to greater consistency and quality in production.

Training employees to identify waste and encouraging continuous improvement fosters a culture where efficiency becomes a shared responsibility, further driving down production costs.

Furthermore, adopting tools such as value stream mapping can help visualize the entire fabrication process, making it easier to spot inefficiencies and bottlenecks. By continuously analyzing and refining workflows based on these insights, circuit board manufacturers can enhance operational efficiency.

Ultimately, the integration of lean practices not only results in lower costs but also positions companies to better respond to market demands and technological advancements, ensuring long-term competitiveness in the industry.

The optimization of circuit board manufacturing heavily relies on the implementation of advanced technologies, especially in automation and quality control. According to a report from the IPC, the adoption of automation in PCB production can lead to a significant reduction in production time—by as much as 30%—while enhancing precision. Automated processes minimize human errors and streamline assembly lines, enabling manufacturers to achieve higher throughput and lower operational costs. As PCBs become increasingly complex, integrating advanced robotics and automated inspection systems has become imperative for maintaining efficiency.

Furthermore, leveraging advanced quality control measures, such as machine vision systems and artificial intelligence, can drastically improve defect detection rates. Research from the Electronics Industry Citizenship Coalition (EICC) indicates that incorporating AI-driven analytics can reduce defect rates by up to 25%. These technologies not only ensure that problems are identified early in the production process but also provide manufacturers with actionable insights that can lead to continuous improvement in quality. Investing in these innovations not only enhances product reliability but also positions manufacturers competitively in a marketplace that demands higher quality and efficiency.