The electronics manufacturing industry is continuously evolving, and 2026 is poised to witness groundbreaking PCB board innovations. Experts in the field, such as Dr. Emily Chen, emphasize the importance of staying ahead in technology. She stated, “The future of PCB boards lies in sustainability and efficiency.” This perspective highlights a crucial shift in focus.

Recent advancements prioritize eco-friendly materials and efficient production processes. Innovations include flexible PCB boards and improved design software. These changes can significantly reduce waste and enhance product performance. However, the rapid pace of innovation brings challenges. Many manufacturers struggle to adapt to new technologies.

As we look toward 2026, it is clear that the PCB board industry faces both exciting opportunities and daunting hurdles. Adaptability will be key. The quest for sustainability may lead to complex decision-making. Ultimately, the choices made today will define the future landscape of electronics manufacturing.

Emerging trends in PCB design for 2026 will significantly reshape electronics manufacturing. A recent report by IPC highlights that the demand for smaller, more efficient boards is at an all-time high. With 5G and IoT technologies on the rise, smaller form factors are crucial. Compact PCBs offer more functionality. Yet, there are challenges in thermal management and signal integrity.

Sustainability is another key trend for 2026. Data suggests that 60% of manufacturers are prioritizing eco-friendly materials. This shift reflects a growing concern about environmental impact. However, the transition to green materials can complicate the design process. Manufacturers often face difficulties in sourcing sustainable components that meet performance standards.

Additionally, flexible PCBs are gaining popularity. They enable unique designs and applications in wearable technology and automotive sectors. A study indicates that the market for flexible circuits will grow by 18% annually through 2026. Yet, this innovation does not come without obstacles. The production cost remains high, and design complexities can lead to errors. Balancing innovation with manufacturability is a pressing issue for designers and engineers alike.

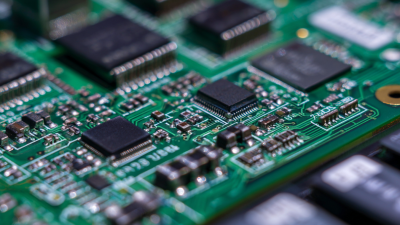

In the evolving world of electronics, printed circuit boards (PCBs) face a growing demand for durability and performance. Advancements in materials are crucial for meeting these challenges. For instance, high-frequency laminates reduce signal loss and enhance performance in communication devices. These materials help in creating compact designs that are efficient and powerful.

Another significant development is the use of flexible substrates. These allow for innovative shapes and components in electronic devices. But they also bring challenges. Flexibility can lead to stress points that may compromise the circuit integrity over time. Thoughtful designs are needed to minimize such risks.

Additionally, eco-friendly materials are gaining traction. They offer a sustainable alternative for manufacturers but can have varying performance characteristics. Balancing environmental impact and durability is complex. Continuous research is essential. These advancements promise a bright future, but they also require careful consideration and adaptation.

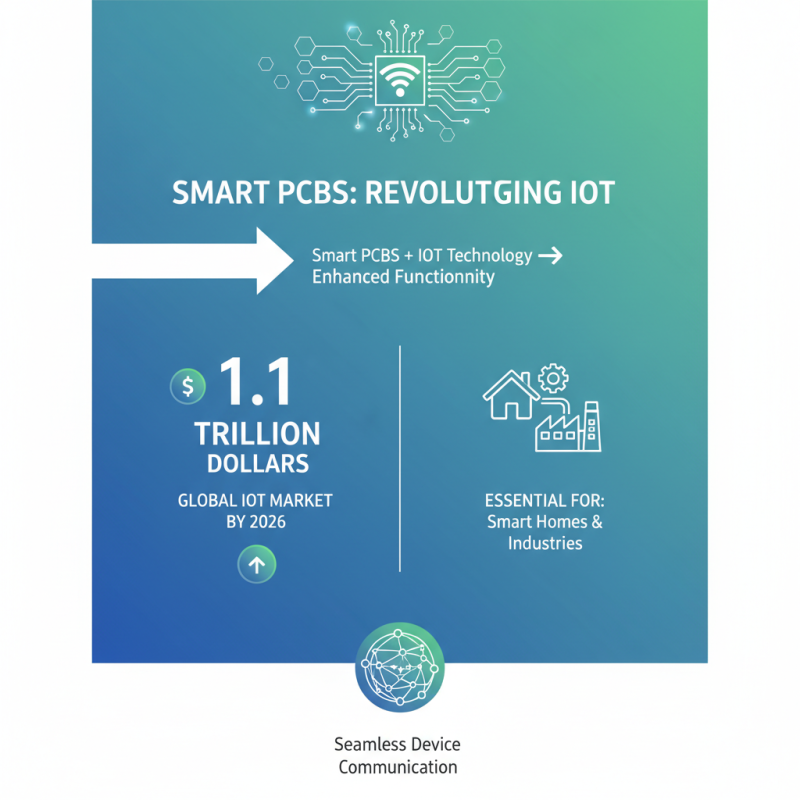

Smart PCBs are revolutionizing the electronics manufacturing landscape. Integrating IoT technology dramatically enhances functionality. According to a recent report, the global IoT market is expected to reach $1.1 trillion by 2026. Smart PCBs play a crucial role in this growth. They enable seamless communication between devices, making them essential for smart homes and industries.

These advanced PCBs can include sensors and microcontrollers. They collect data and respond to environmental changes in real time. However, challenges remain. Integration can be complex. Many manufacturers struggle with the design phase. Reports indicate that nearly 40% of PCB designs face significant delays during development. Addressing these issues is vital for future innovation.

Moreover, with increased connectivity comes the need for security. Smart PCBs can be vulnerable to cyber threats. Studies reveal that over 60% of IoT devices lack basic security features. This raises concerns about data integrity and device reliability. Manufacturers must prioritize securing these innovations as they pave the way for more interconnected systems.

Sustainable practices in PCB production are essential for an eco-friendly future. Traditional manufacturing methods often generate significant waste. A recent report from the Electronics Industry Citizenship Coalition (EICC) highlights that PCB production can produce up to 2 tons of waste for every ton of circuit boards created. This waste includes hazardous materials that can harm the environment.

Innovations in sustainable production methods are emerging. For example, companies are adopting water-based processes instead of solvent-based ones. This switch reduces volatile organic compounds (VOCs) by up to 60%. Additionally, some manufacturers are utilizing recycled materials. According to a study by the Institute of Electrical and Electronics Engineers (IEEE), this approach can lower energy consumption in production by 30%.

Nevertheless, challenges remain. Many manufacturers still use outdated processes due to cost concerns. Transitioning to greener methodologies often requires significant upfront investment. Furthermore, the recycling process for electronic waste remains unregulated in many regions. As a result, only a small percentage of PCBs are recycled properly. Reflection on these issues is crucial for the industry's future. We must strive for better practices and regulations that protect our environment.

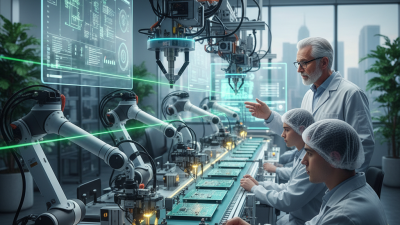

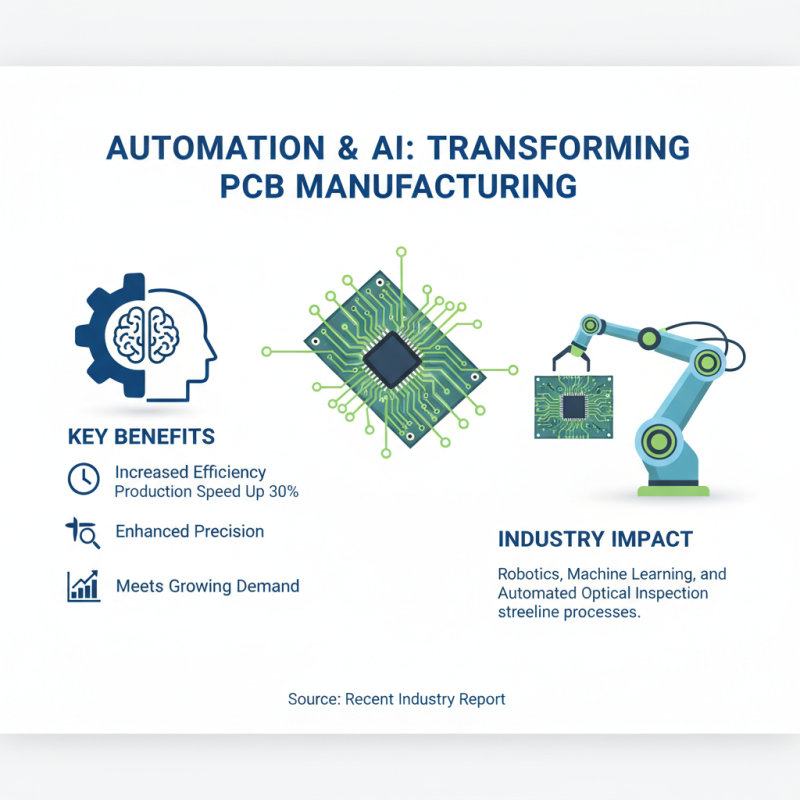

The rise of automation and AI technologies is transforming PCB manufacturing. These innovations drive efficiency and enhance precision. According to a recent industry report, automation can increase production speed by 30%. This is significant for manufacturers looking to meet growing demand.

AI systems optimize design and production workflows. They reduce errors and minimize waste. Data shows that AI can improve defect detection rates by up to 90%. This ensures high-quality outputs while reducing rework cycles. However, integrating these technologies is not without challenges. Many manufacturers struggle with the transition, facing a steep learning curve.

Despite these hurdles, the benefits are clear. Enhanced efficiency and precision can lead to better profit margins. Industry experts predict that companies adopting AI will see a 20% increase in output by 2026. While the path to full automation may be rocky, the long-term rewards are worth considering.